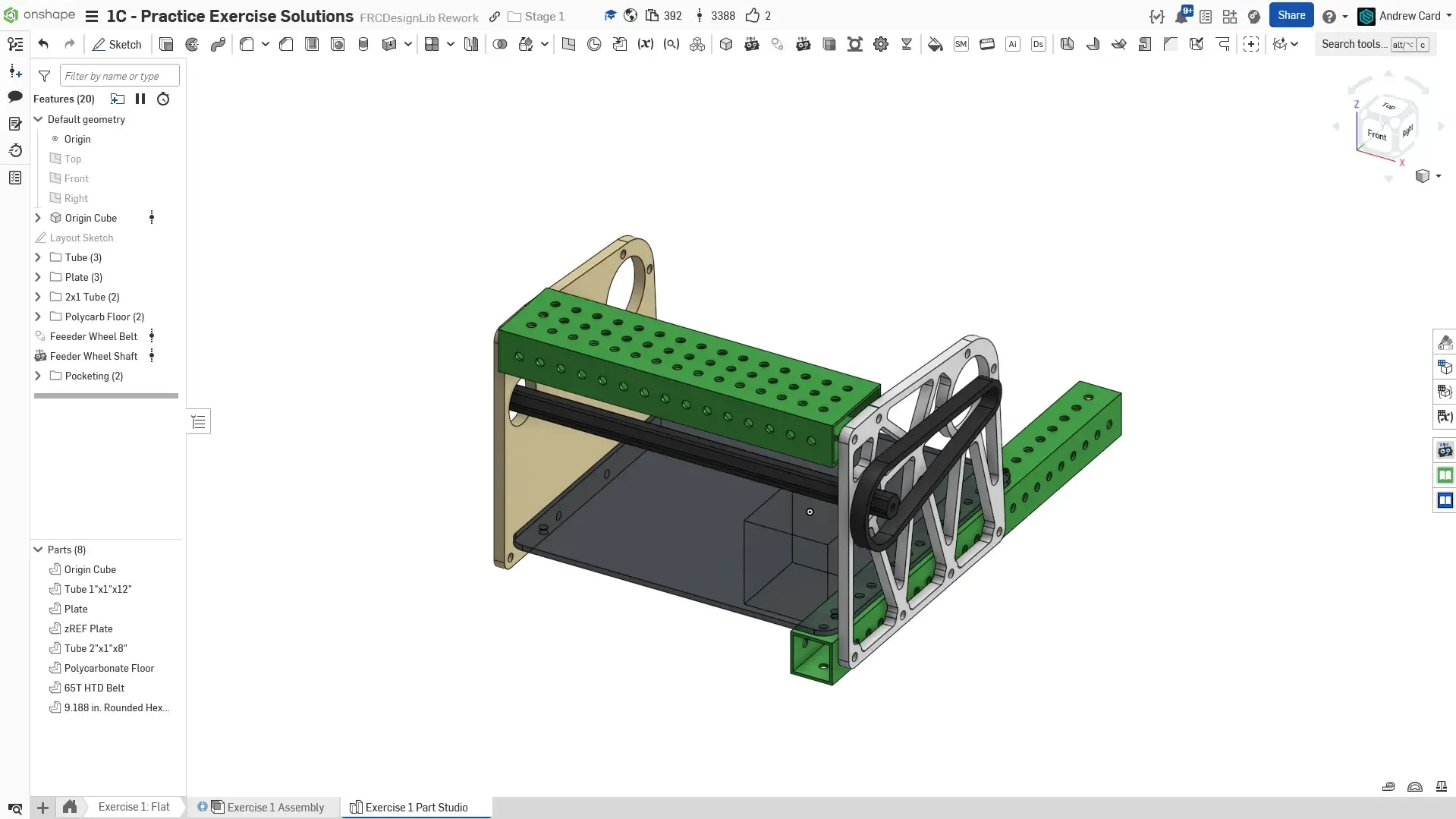

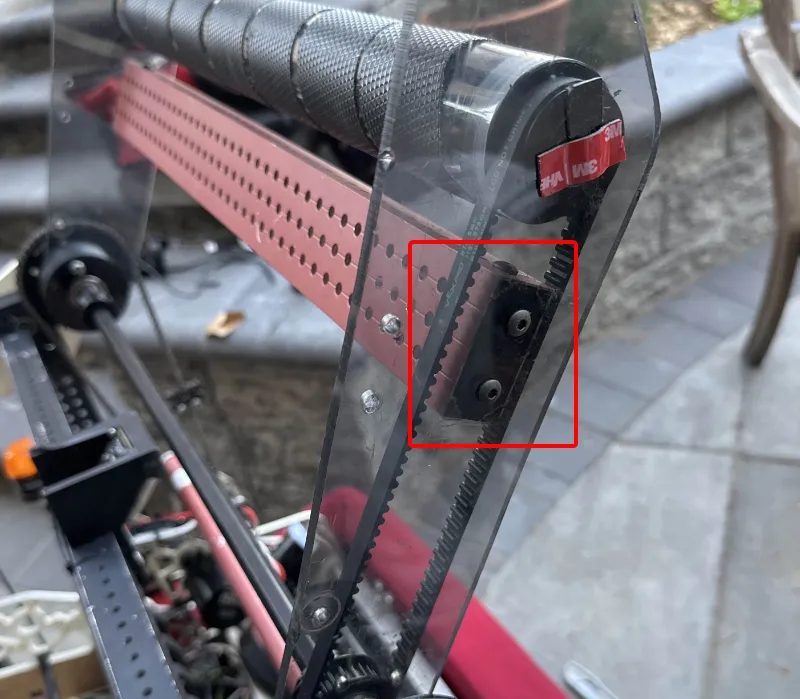

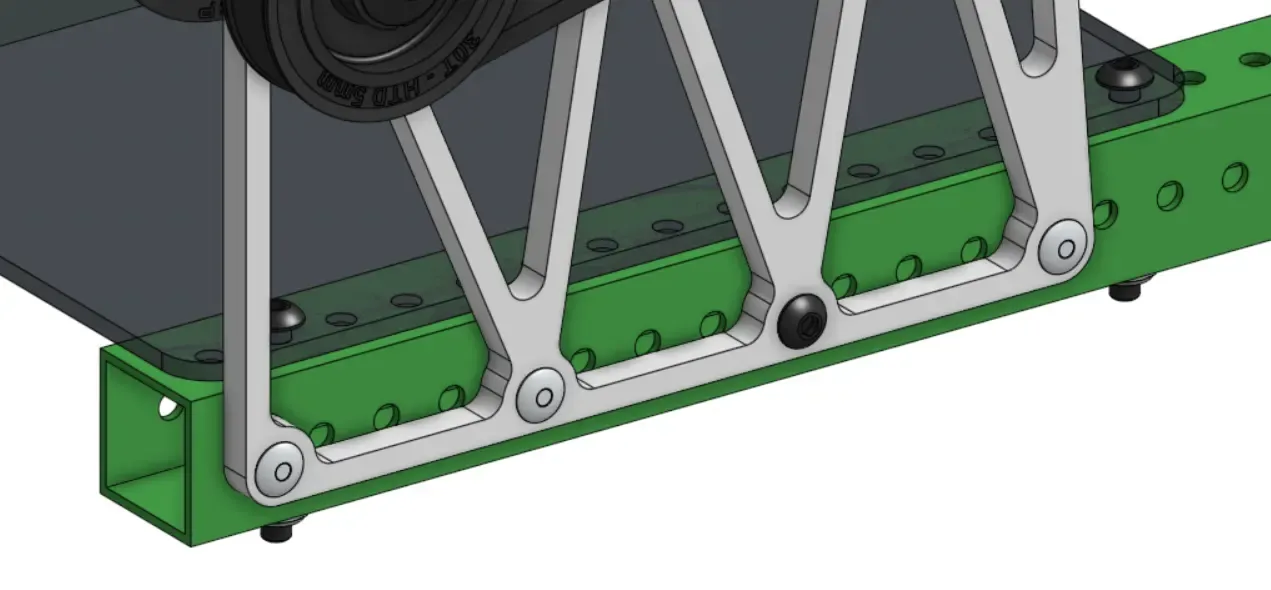

Exercise 1: Flat Intake

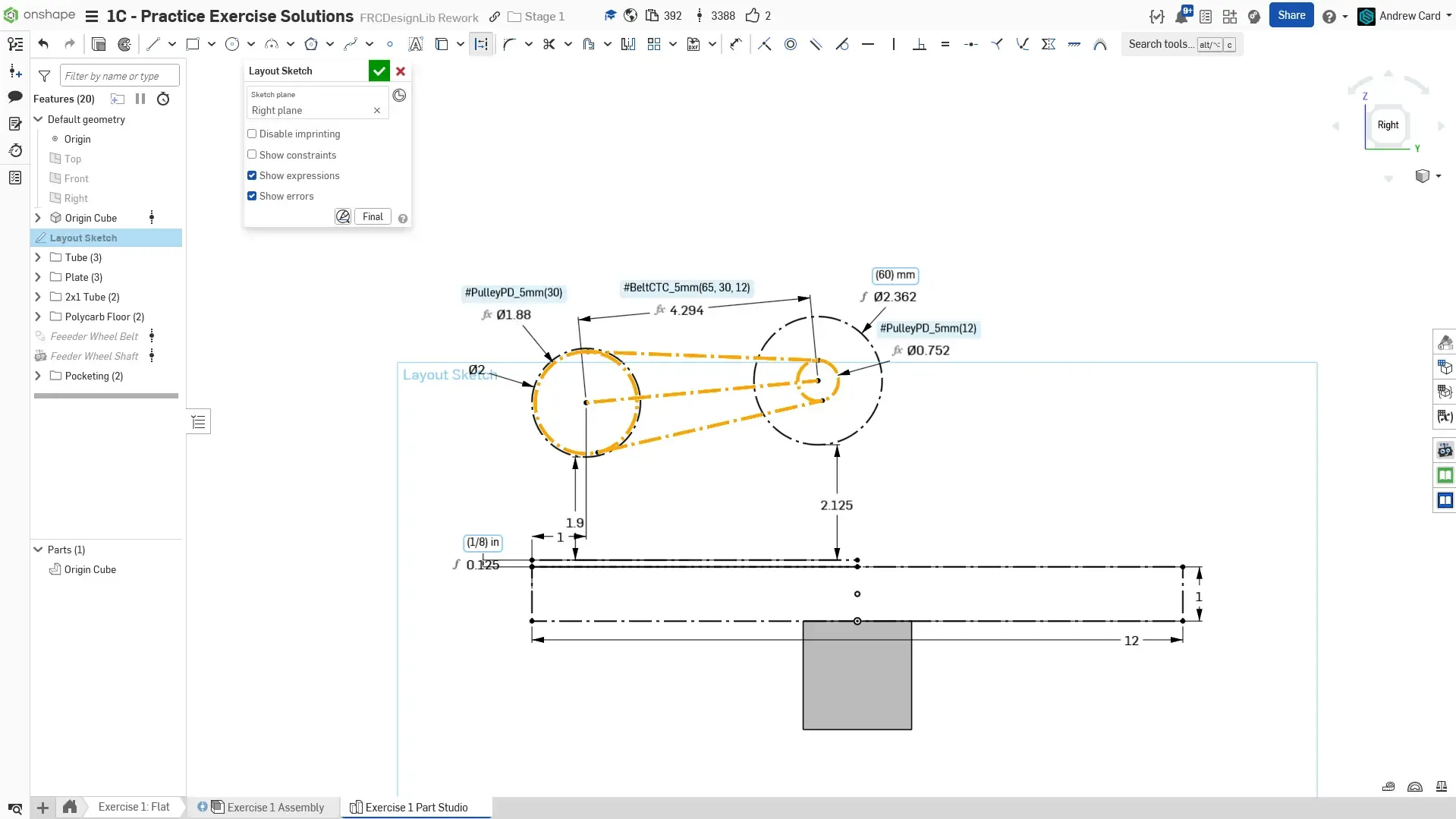

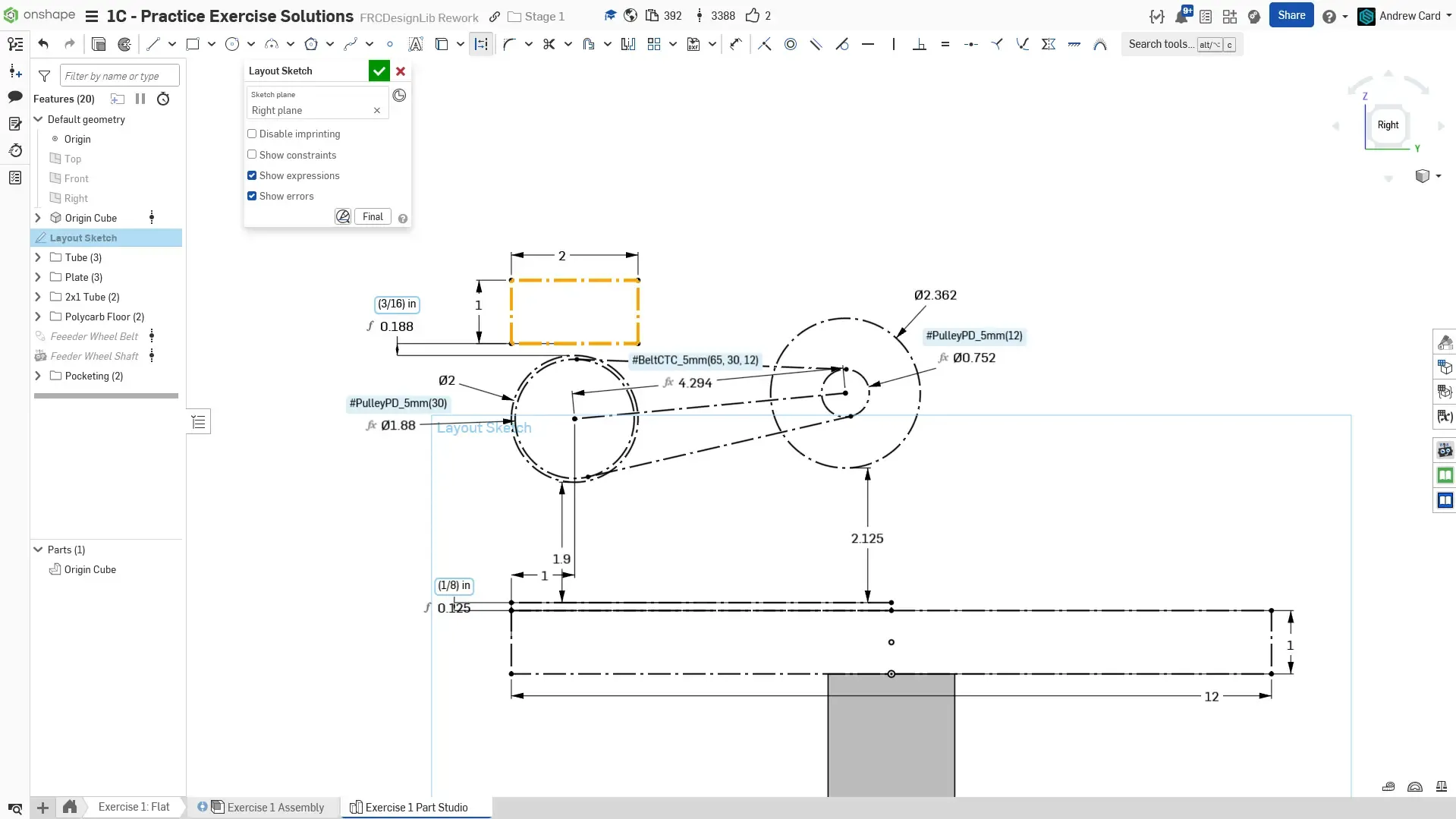

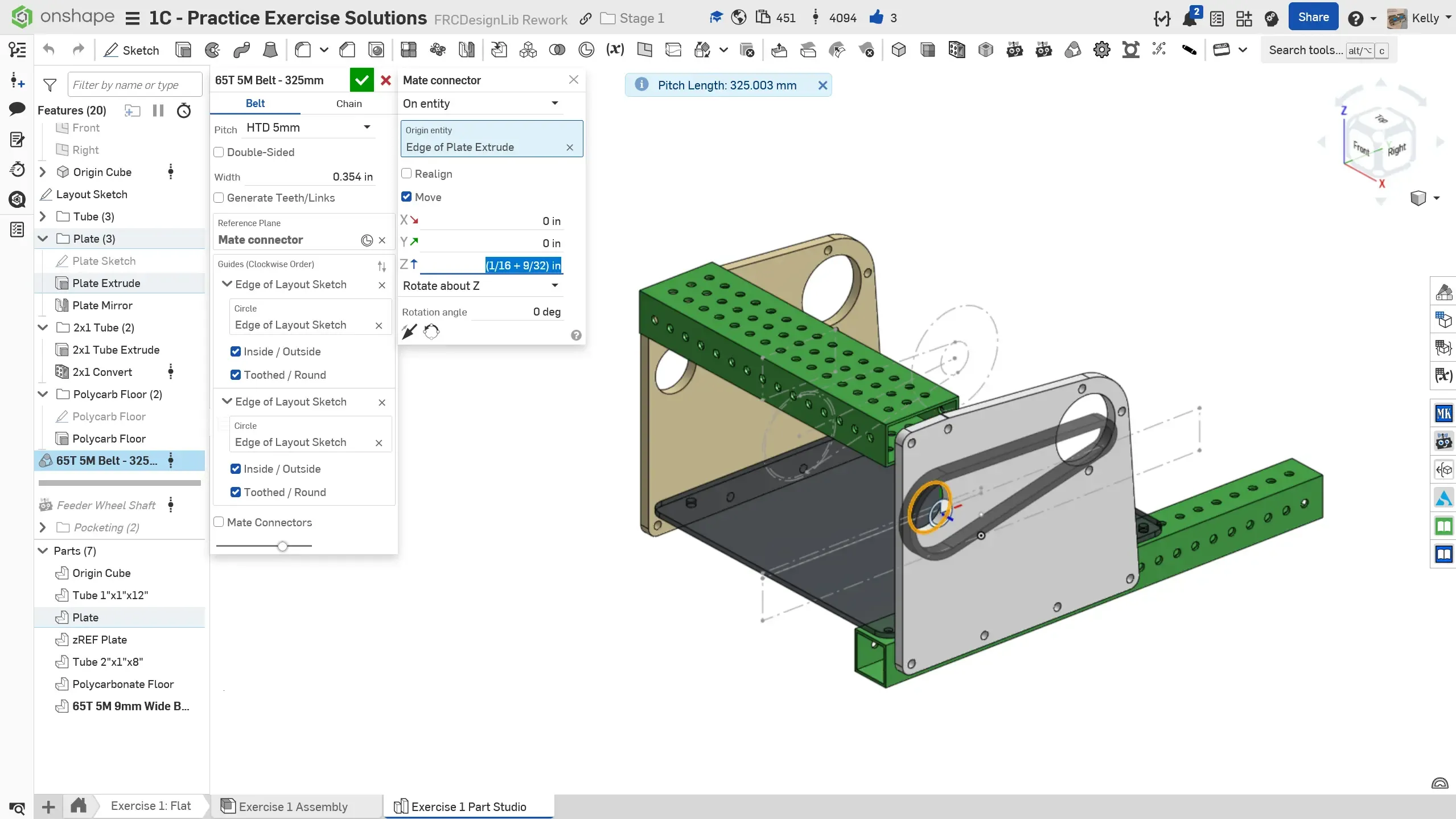

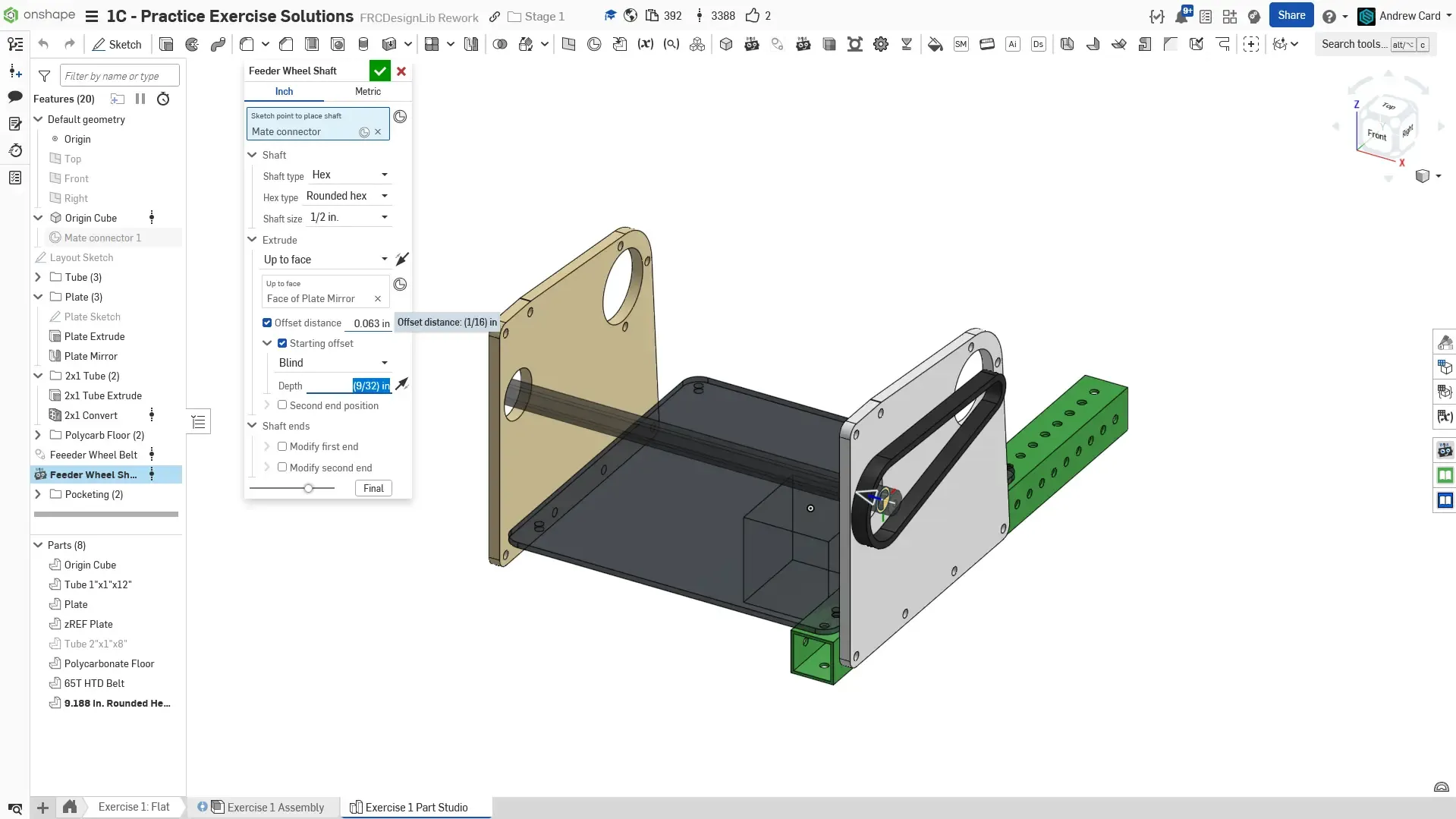

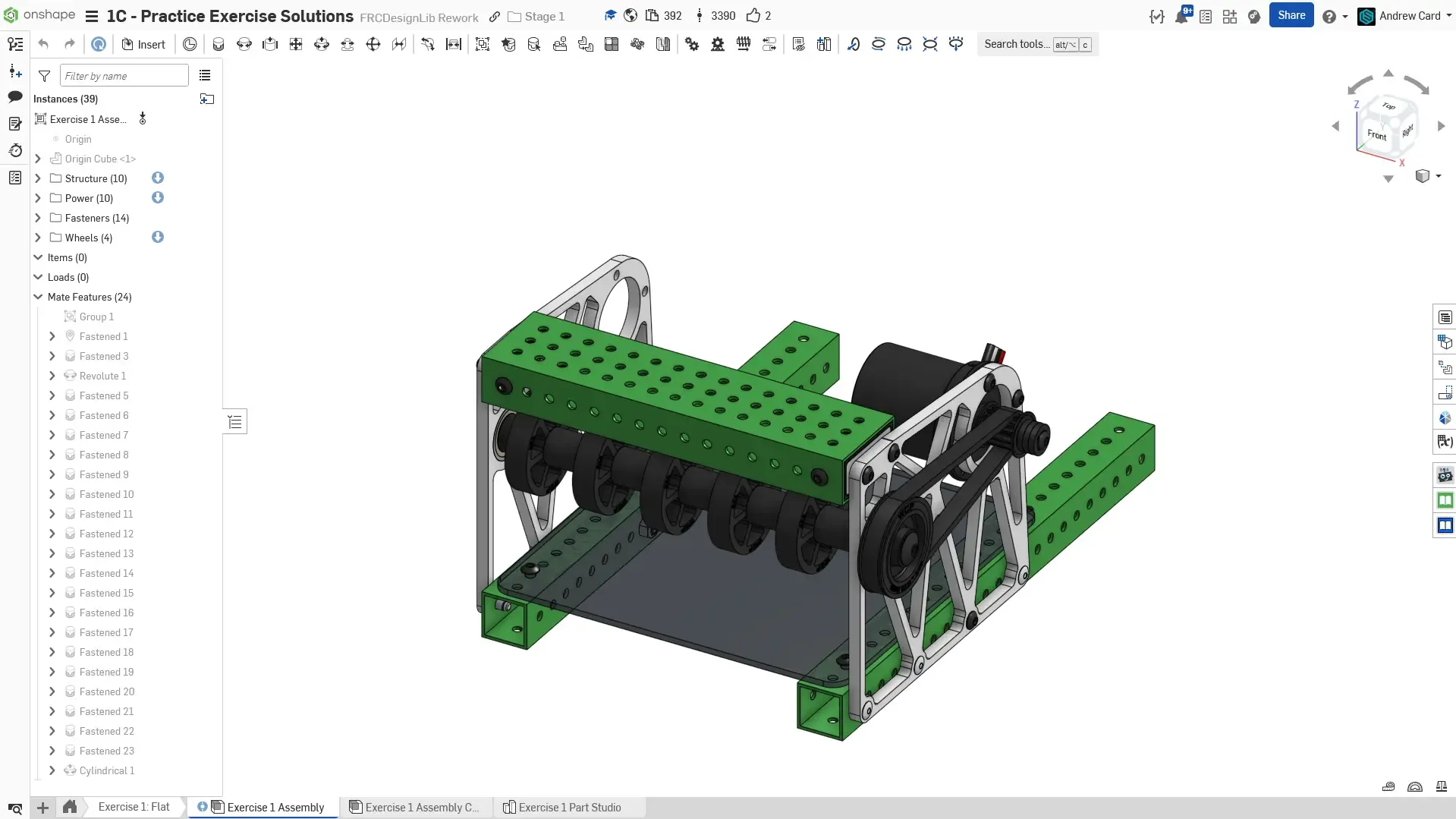

In this exercise, you will be modeling a sort of flat game piece manipulator. This mechanism features live-axle compliant wheels, a belt reduction, and tube plugs.

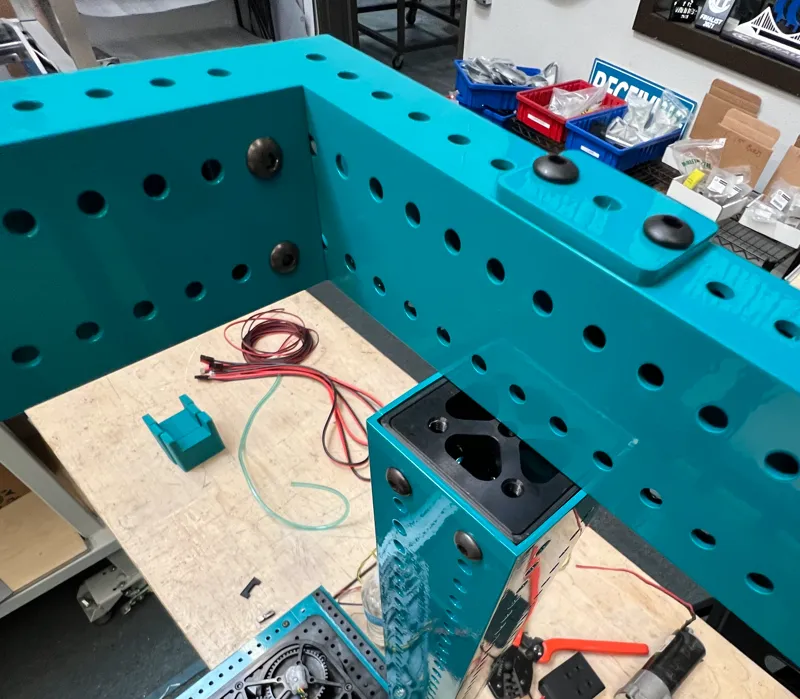

Tube Plugs

Section titled “Tube Plugs”Tube plugs are a great way to build simple and robust structures. Many vendors including WCP, REV, Andymark, and Last Anvil offer in various tubing sizes. They can be used to connect plates to the open face of tubes or to connect tubes to each other without the use of a gusset.

Bolt and Rivet Usage

Section titled “Bolt and Rivet Usage”Throughout the exercises in 1C you’ll pick up several usage techniques for bolts and rivets for different kinds of structures and materials in order to build a strong intuition.

Bolts are strong, and people often use more bolts and rivets than are necessary. When using only bolts, usually you can use 3-4 to fasten corners of a part and be fine, but you may prefer to use rivets to minimize weight or because they don’t go all the way through a tube. In these cases, you can use a number of rivets easily spaced out as long as you have at least one bolt/nut pair per attachment to prevent the rivets from loosening over time. This is done for both this exercise and exercise 8.

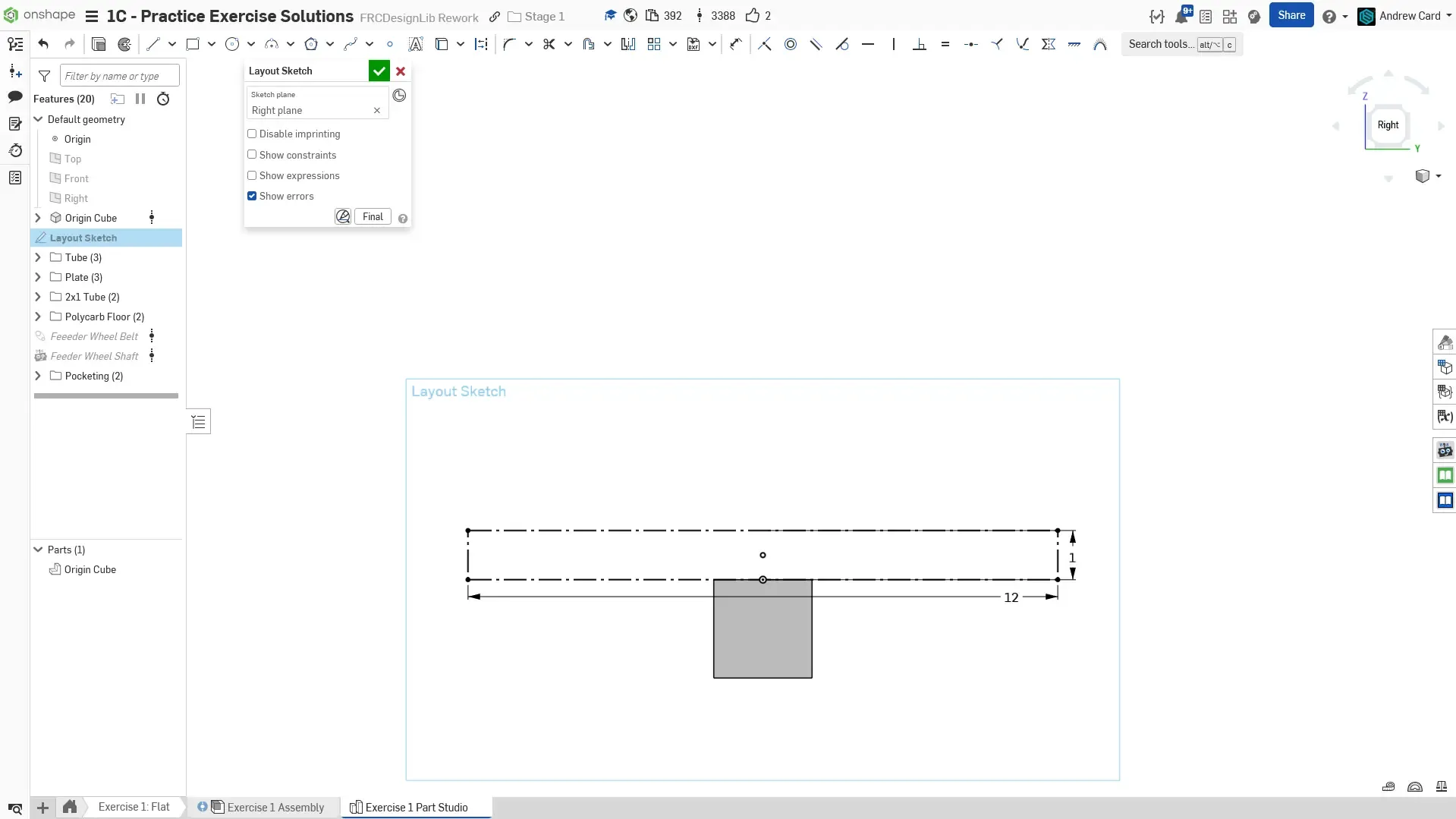

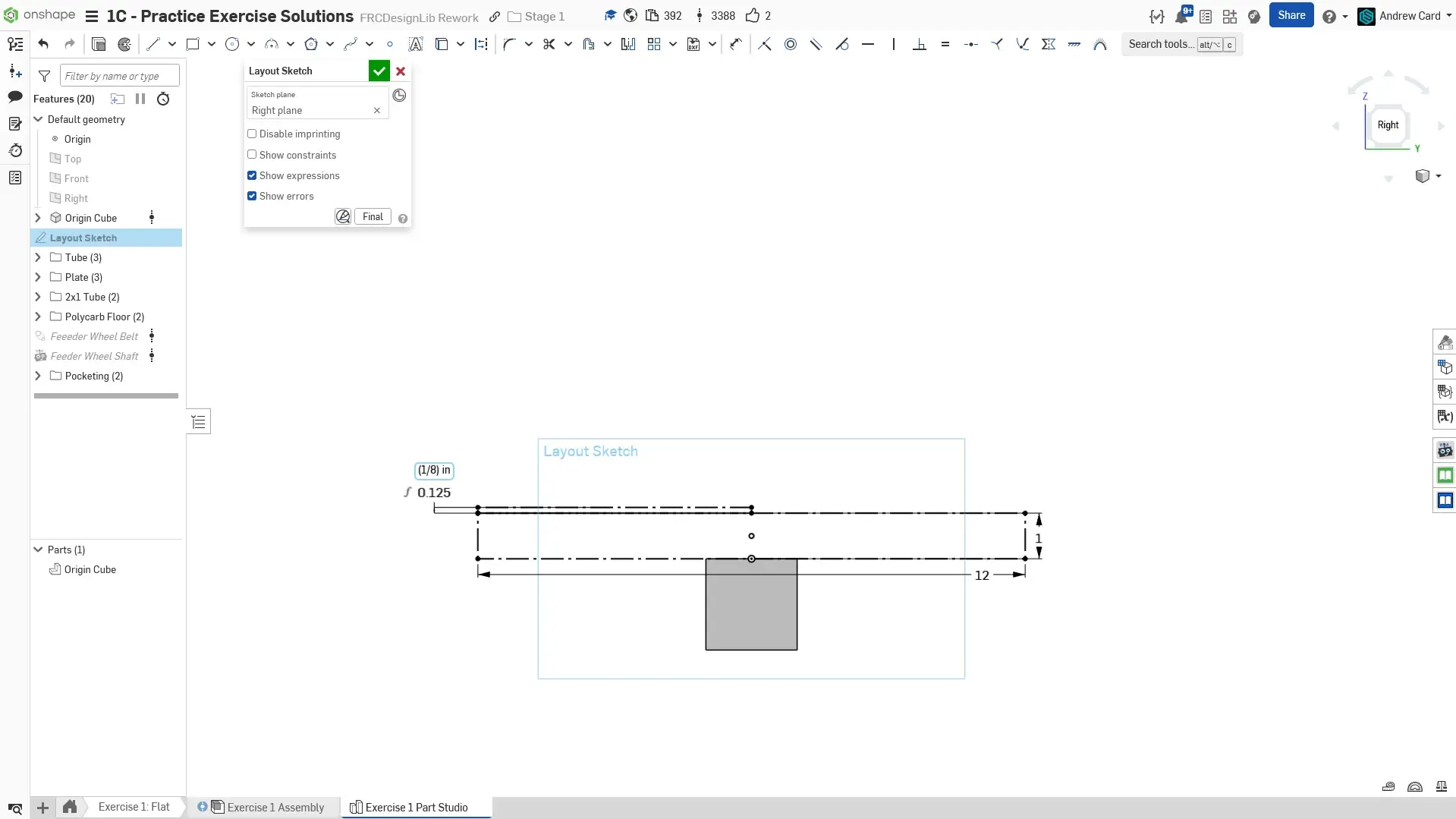

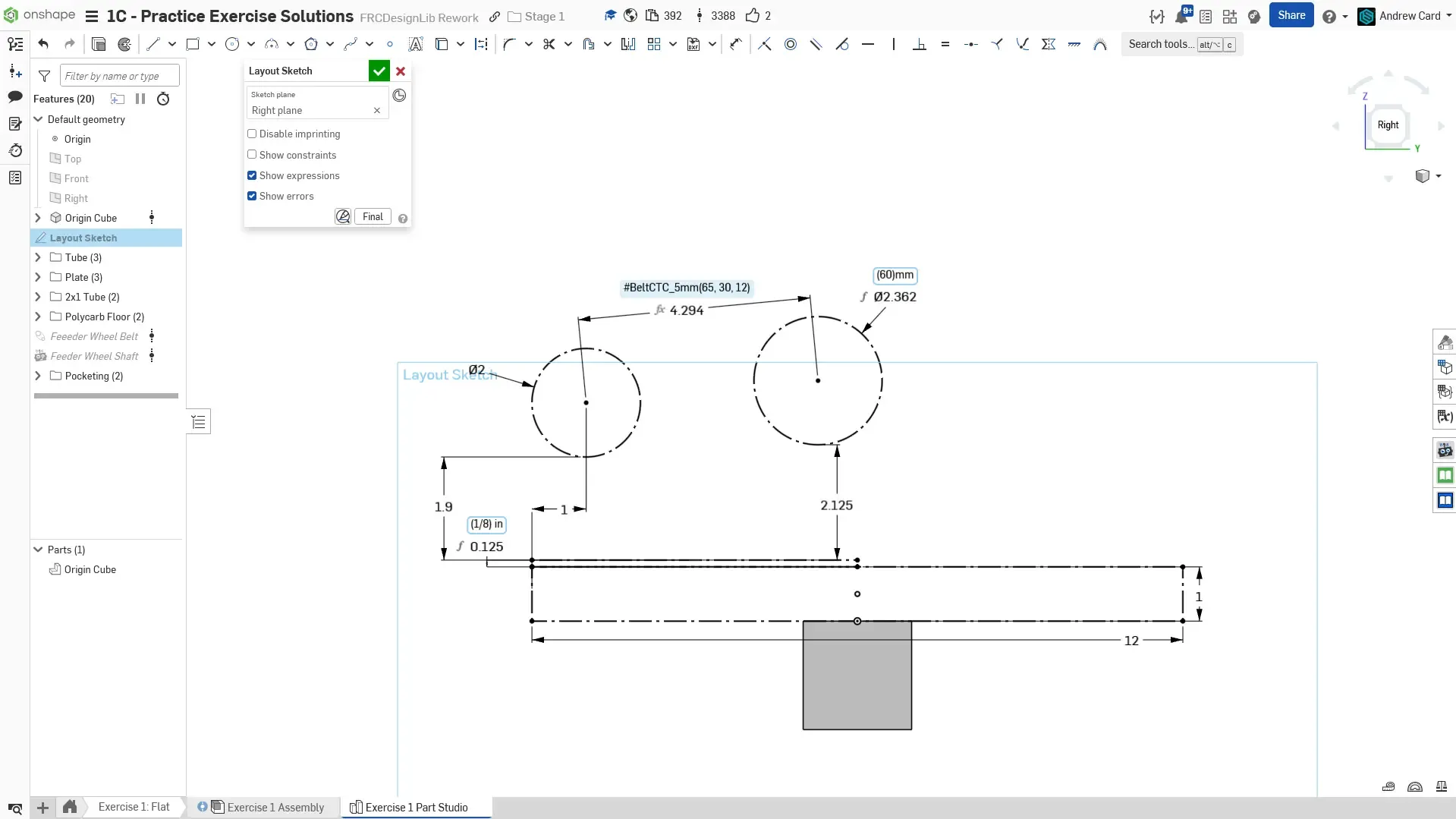

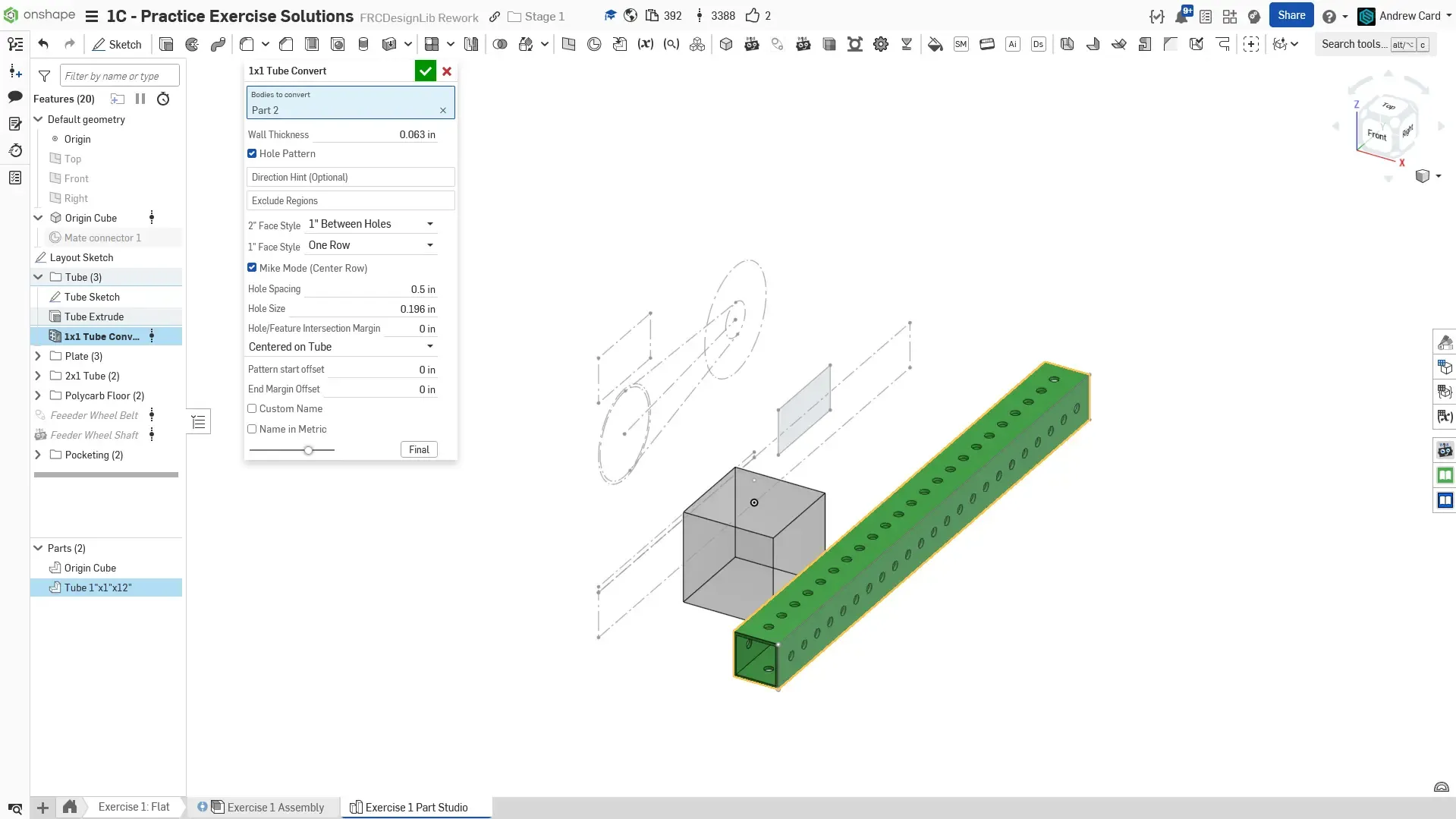

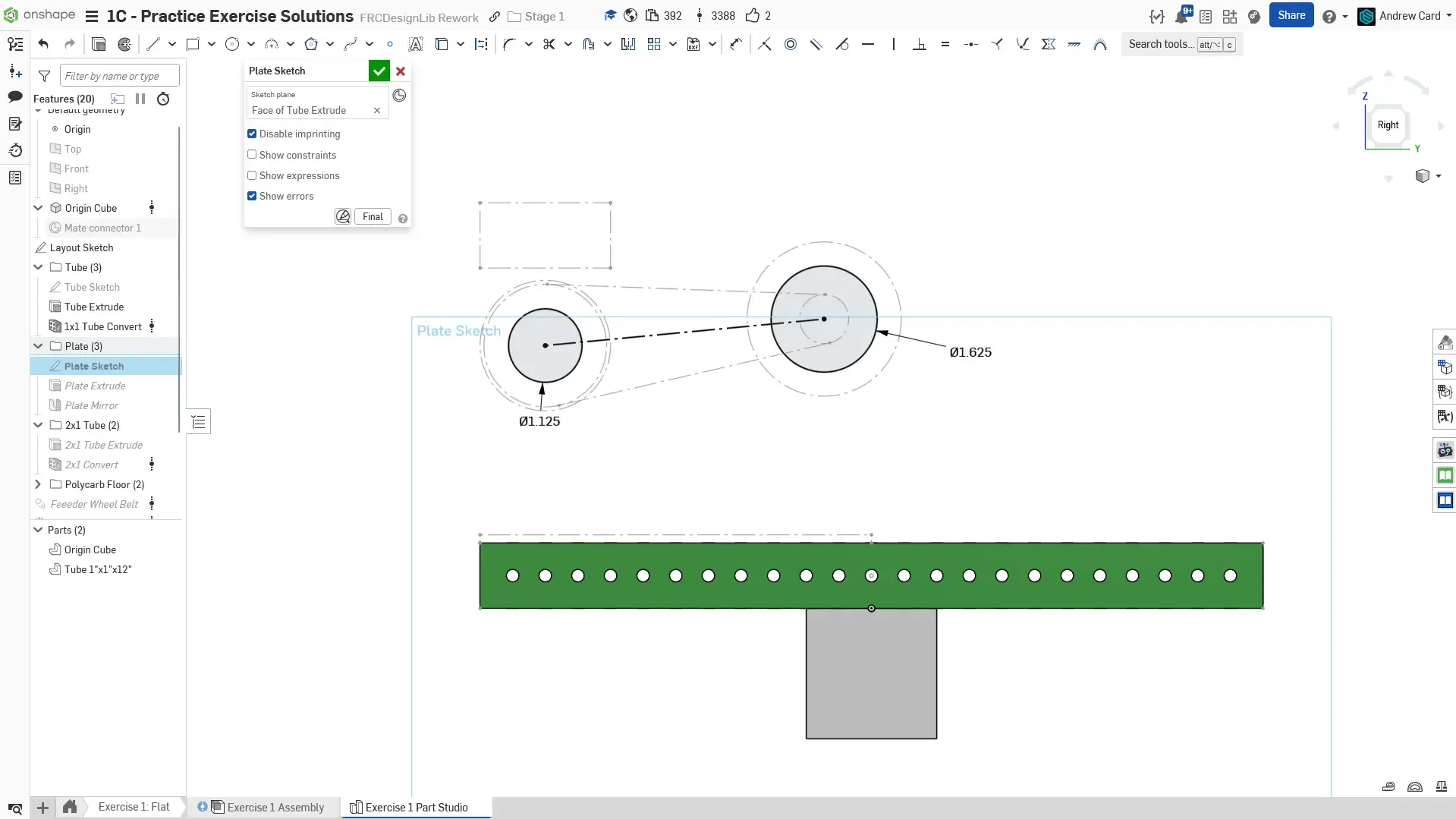

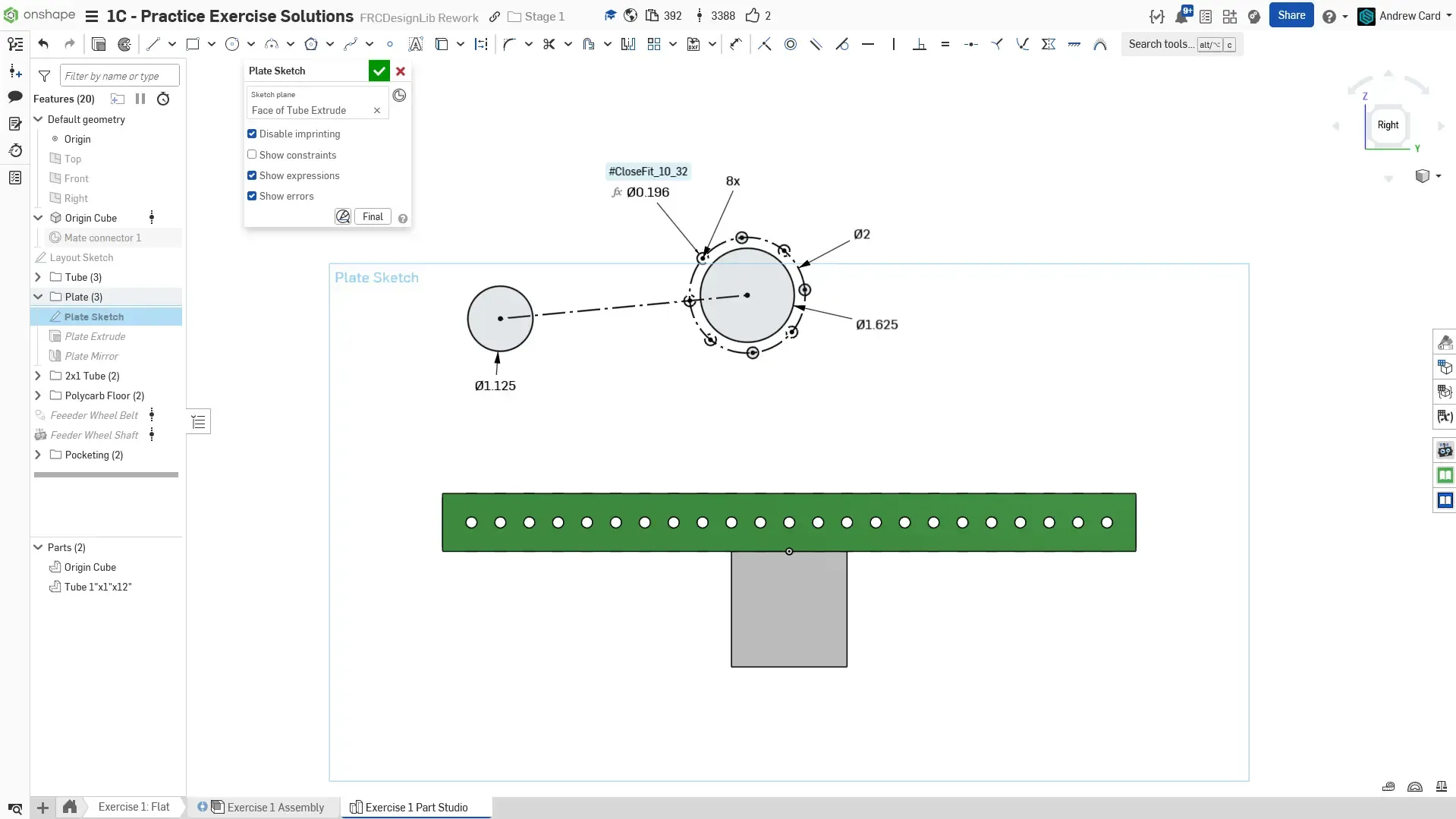

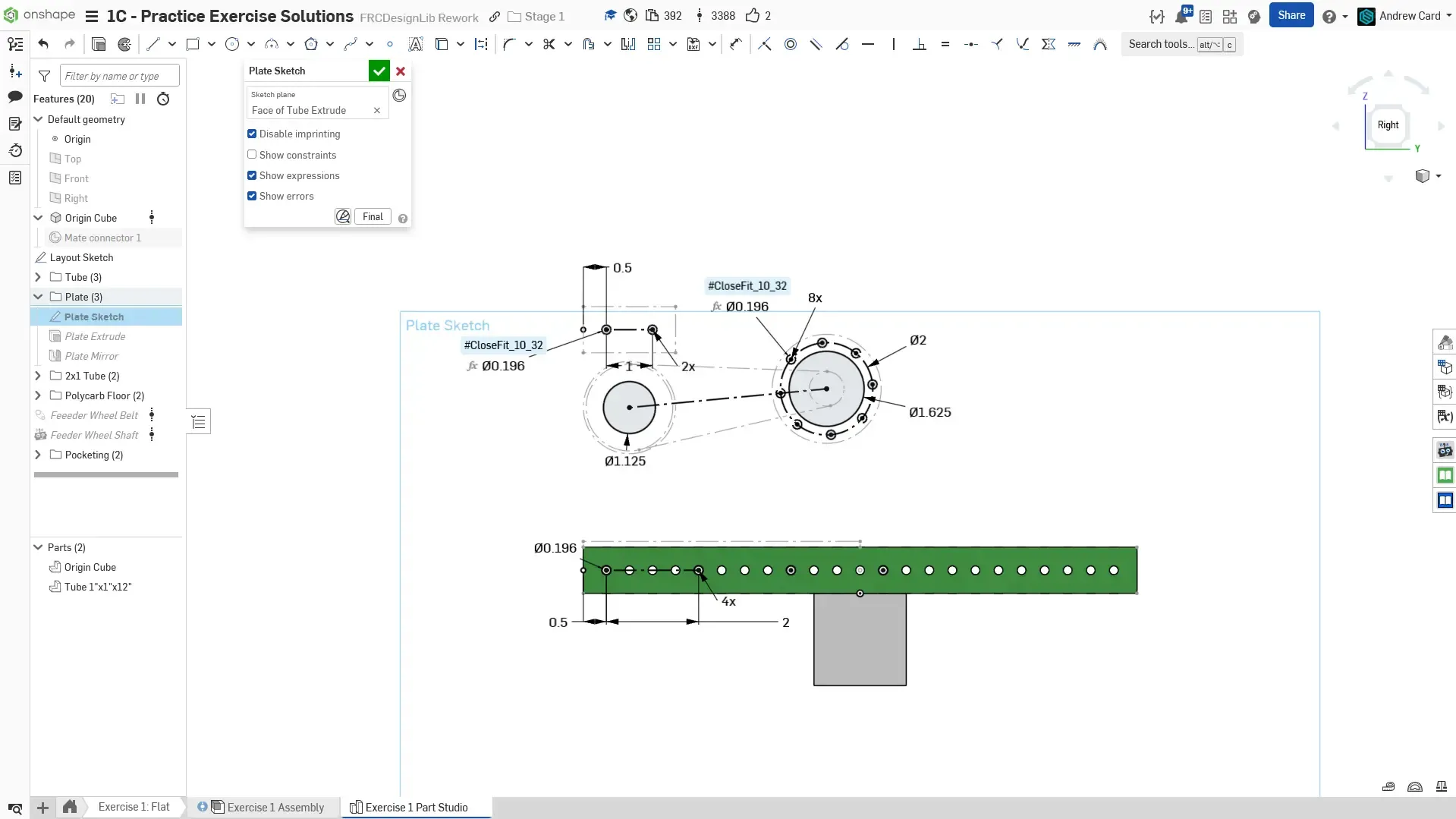

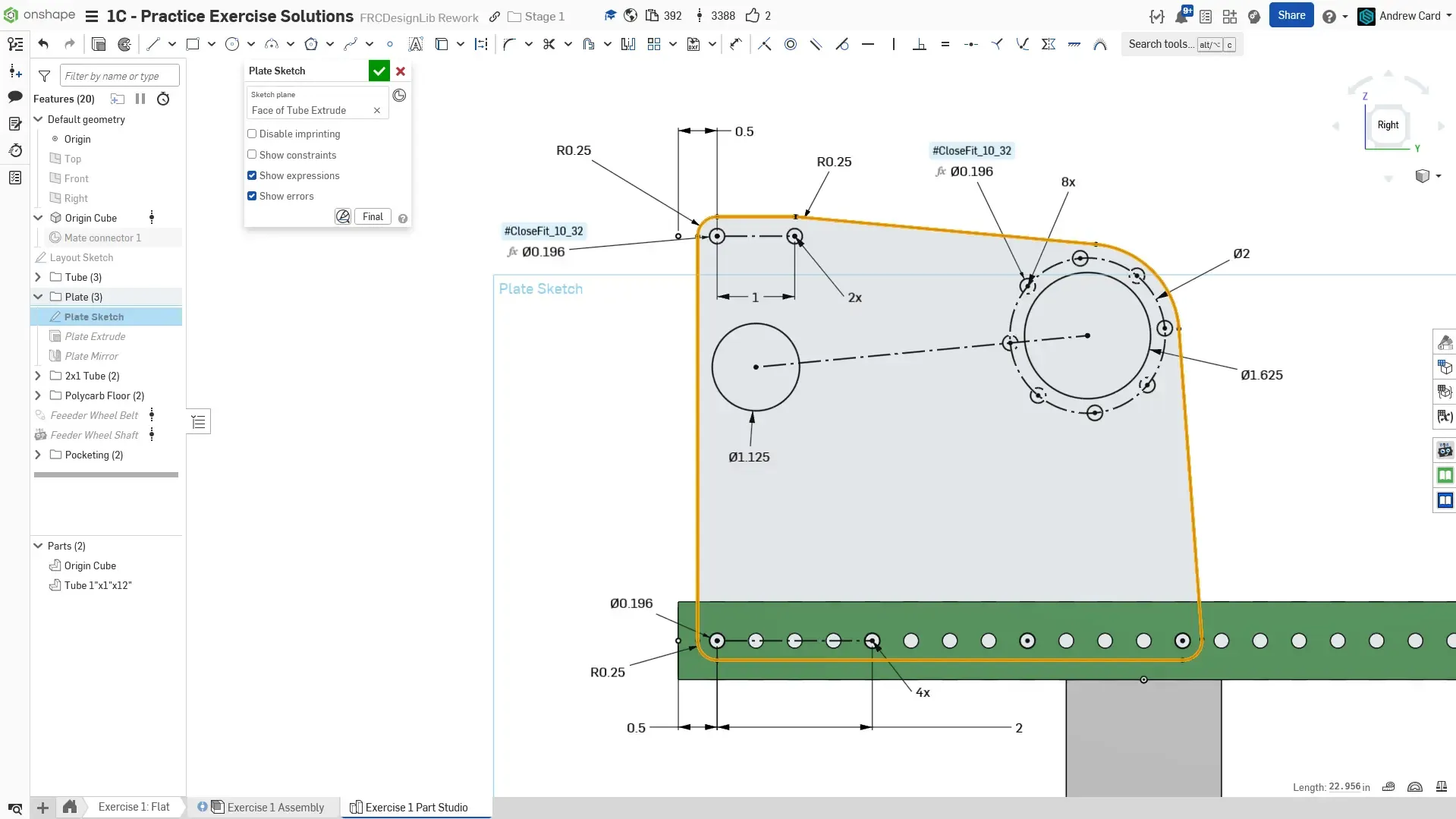

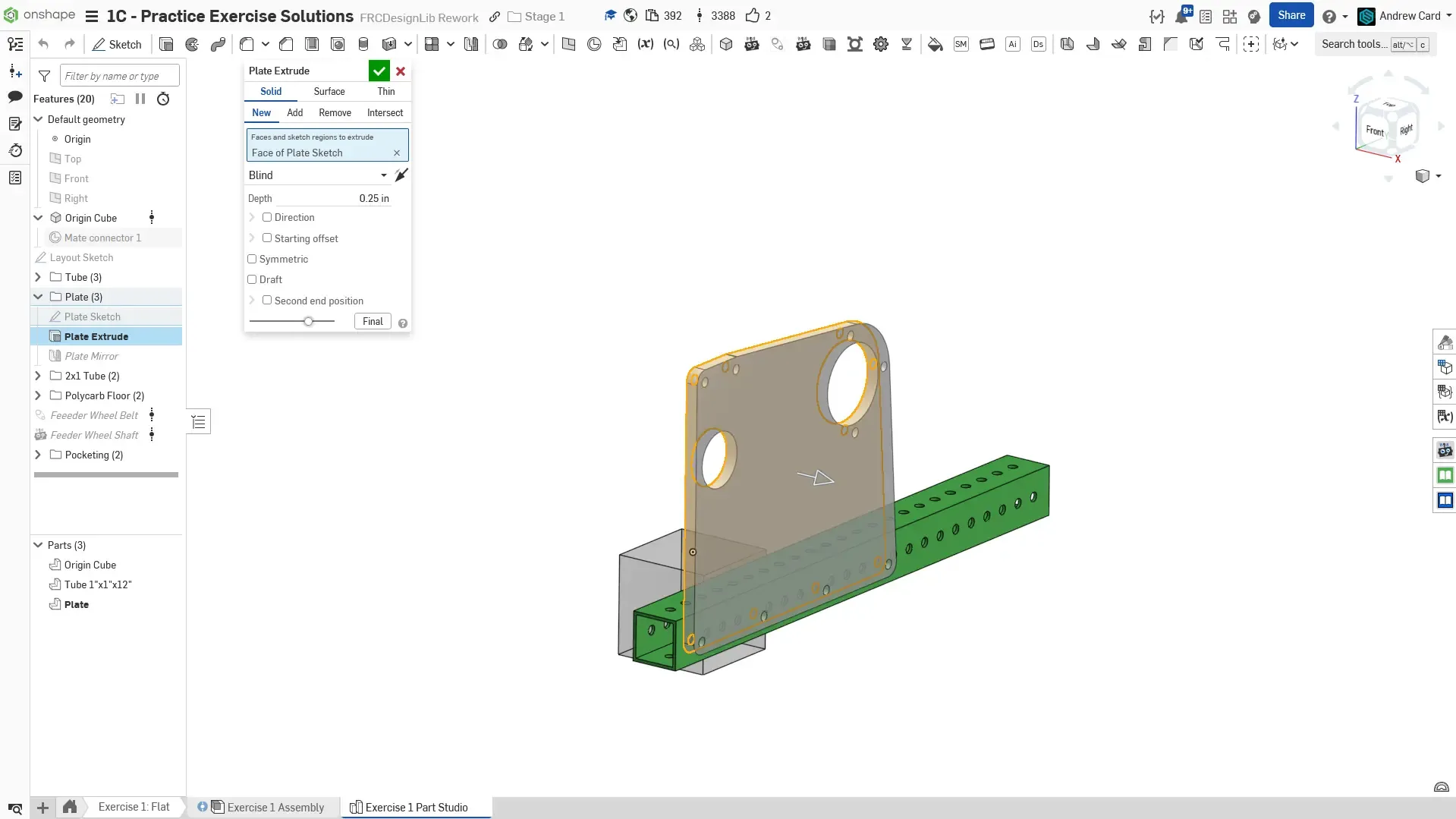

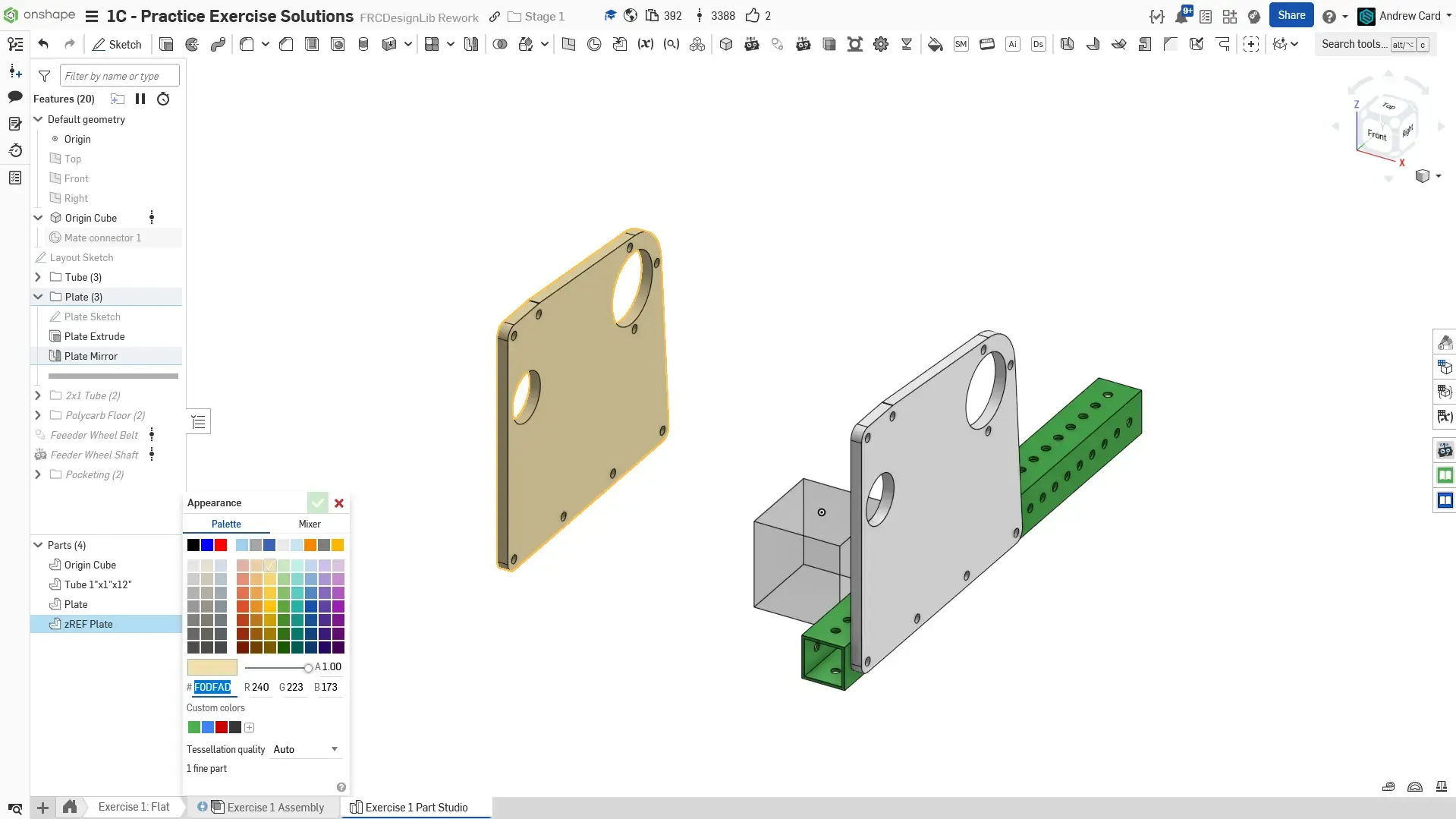

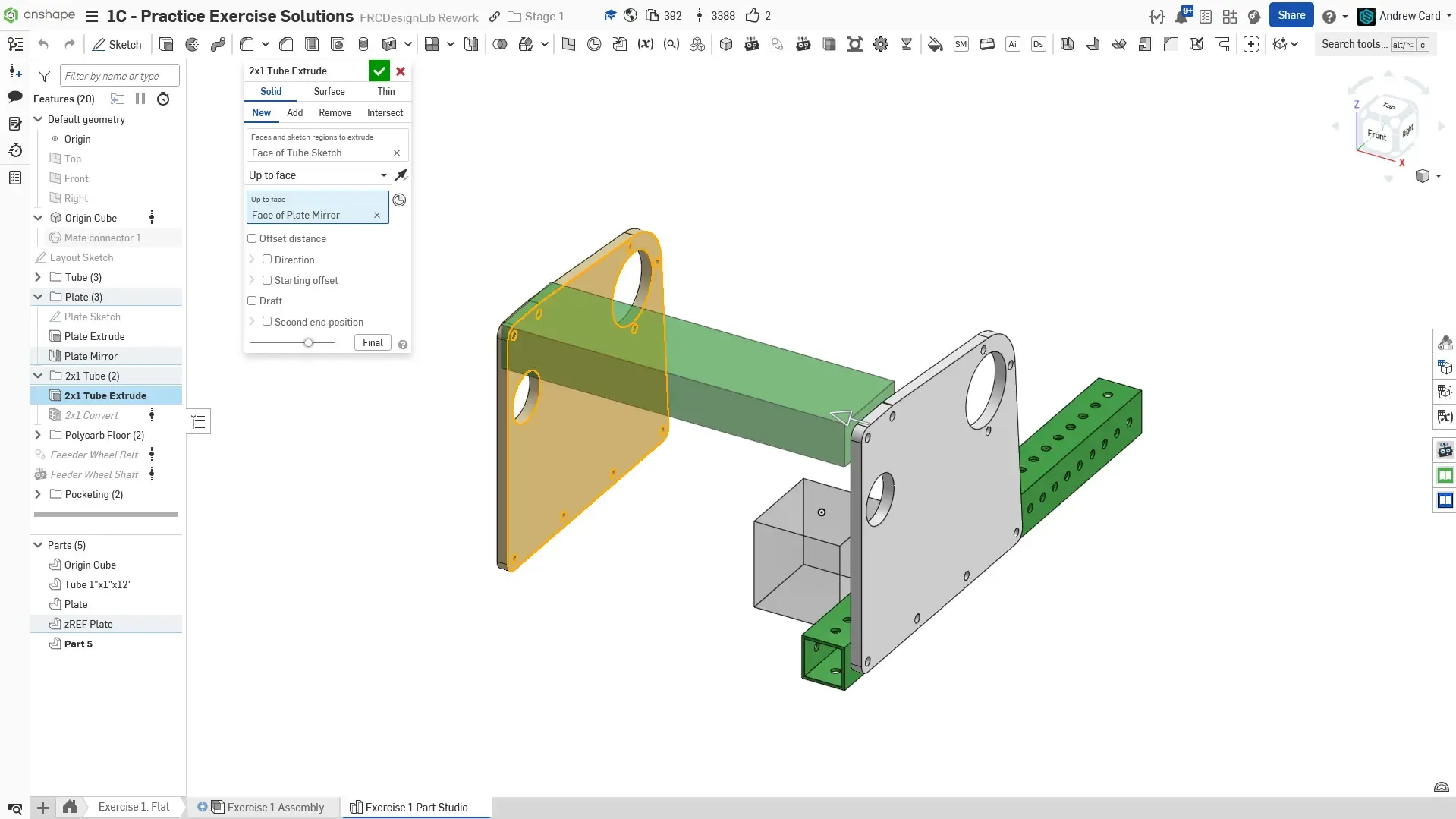

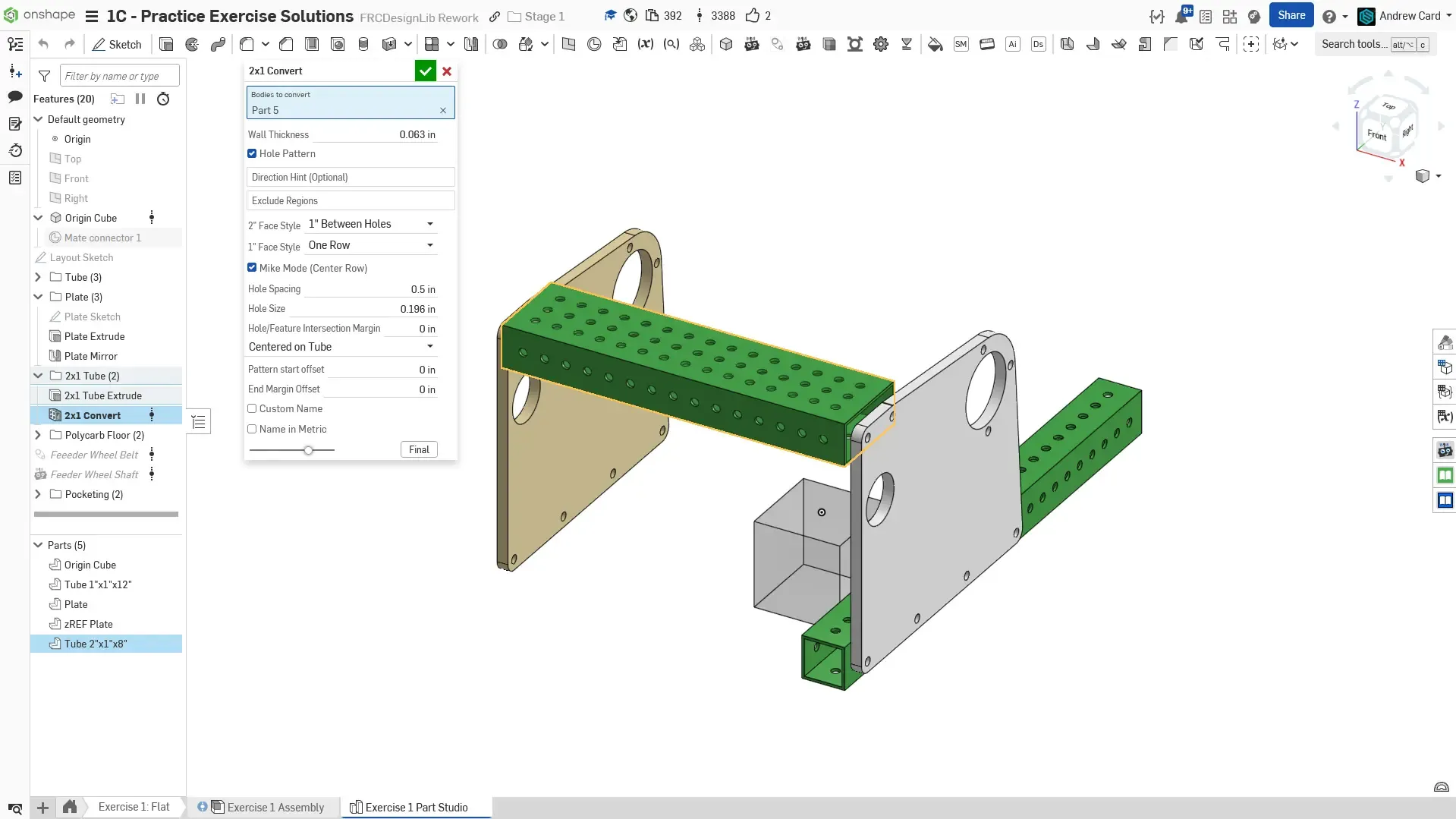

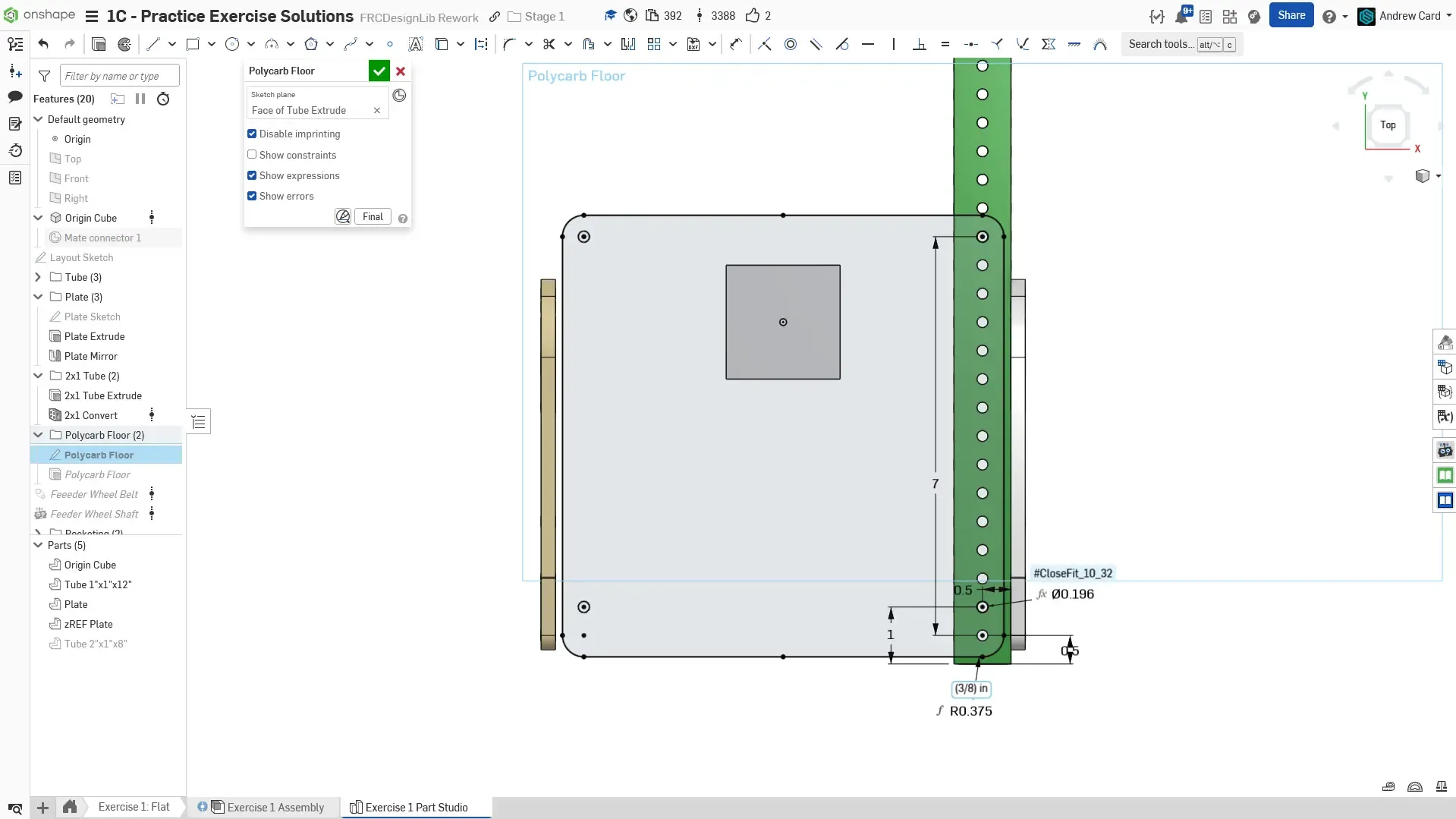

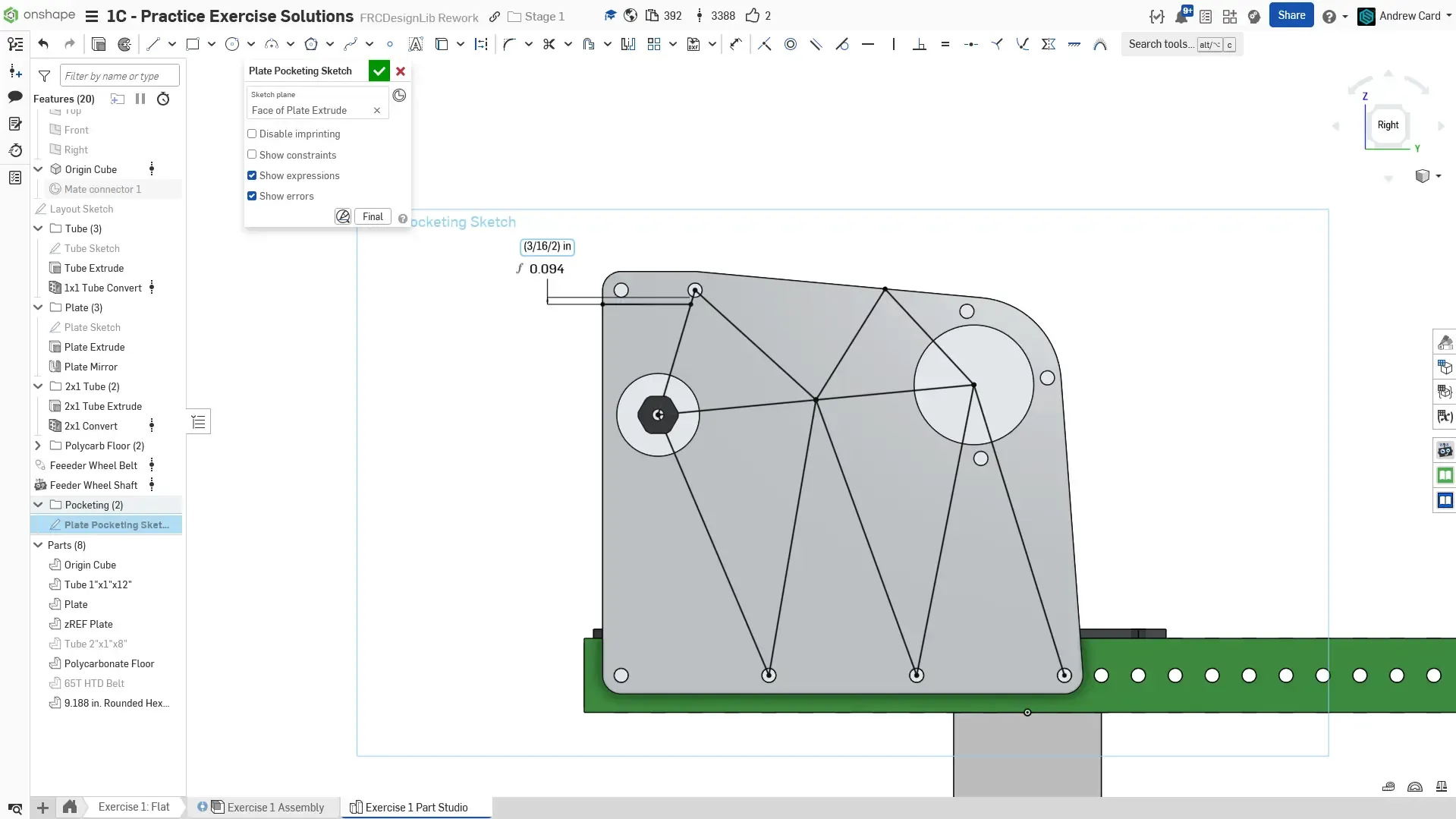

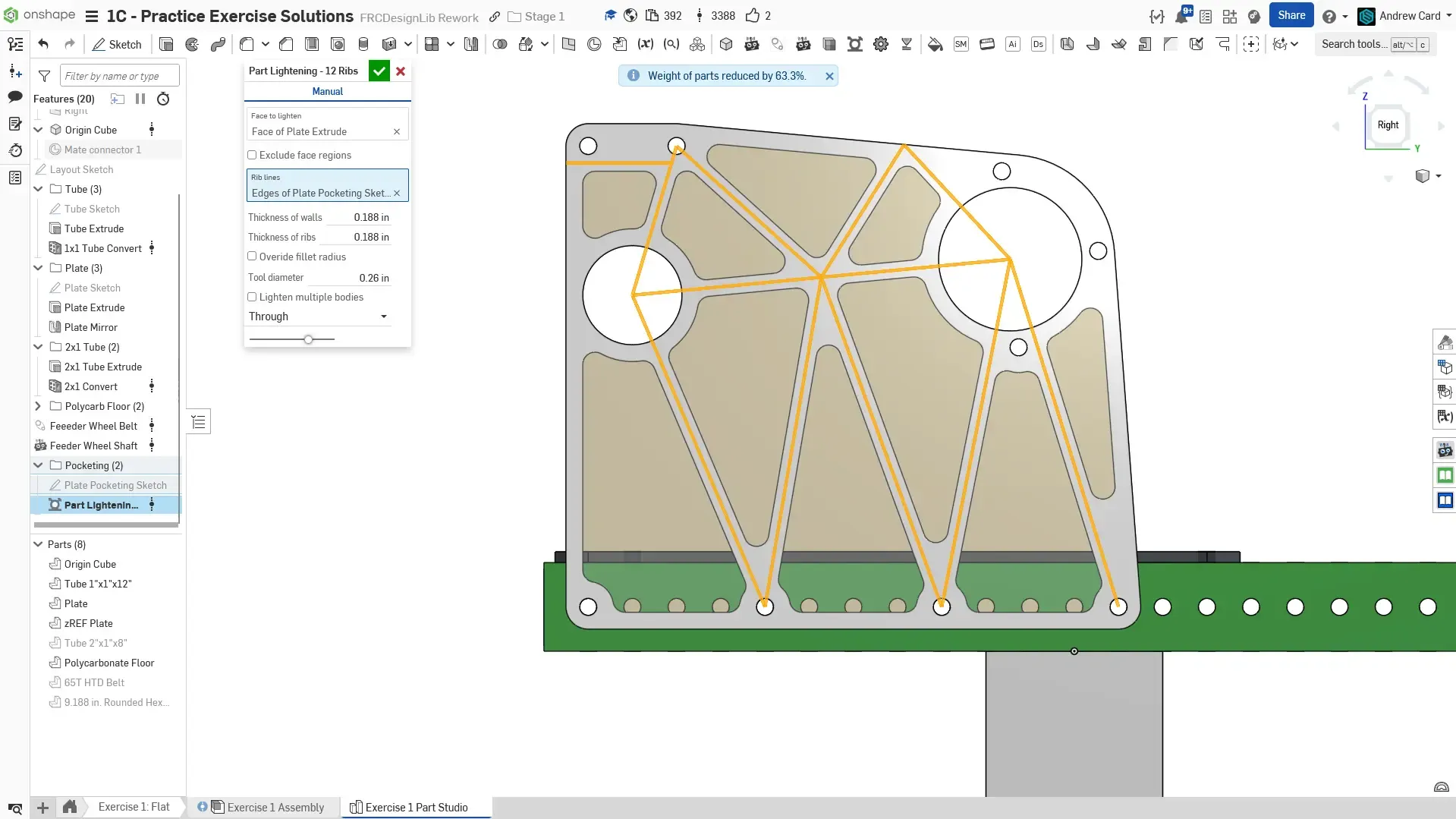

Part Studio Instructions

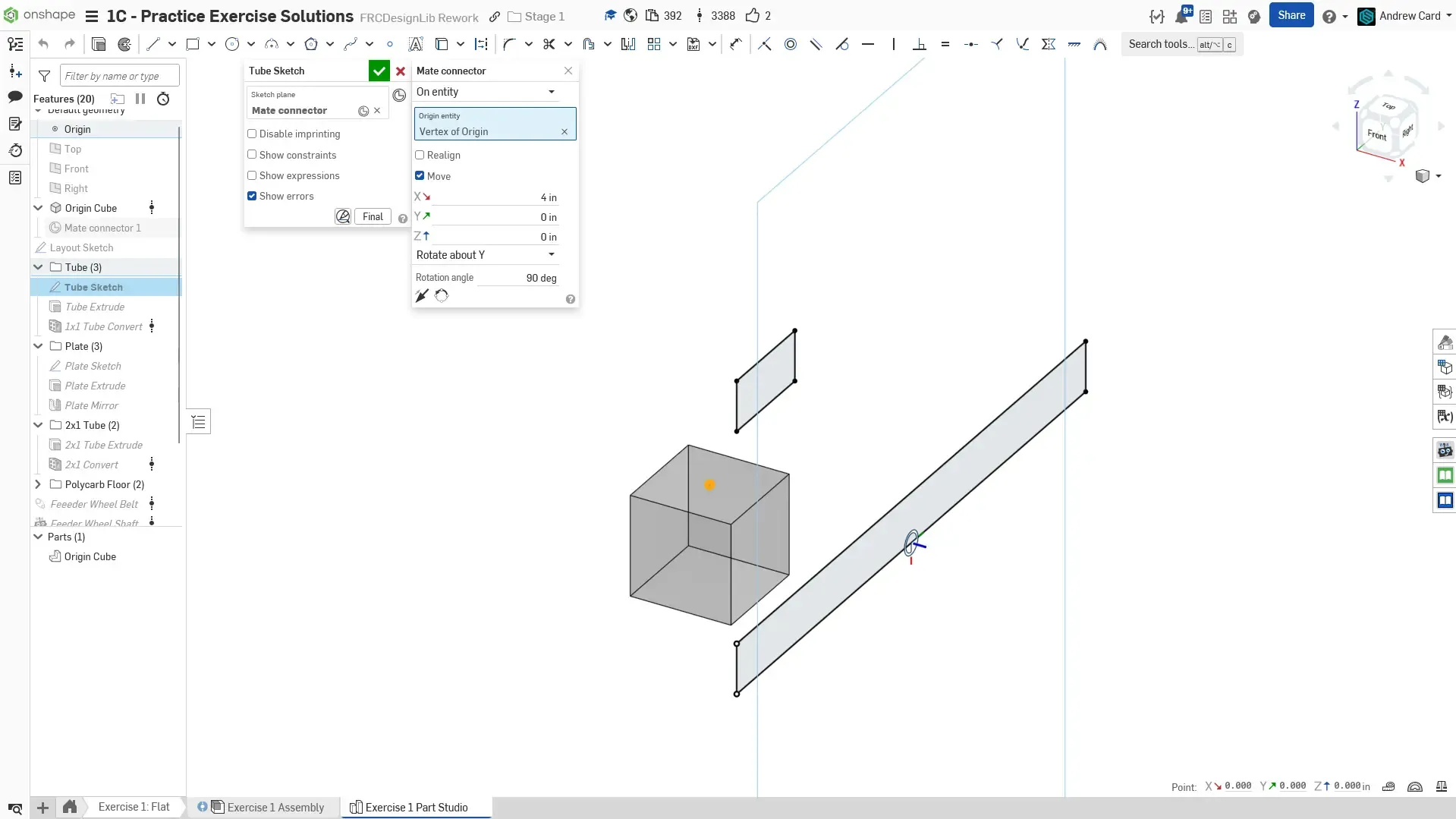

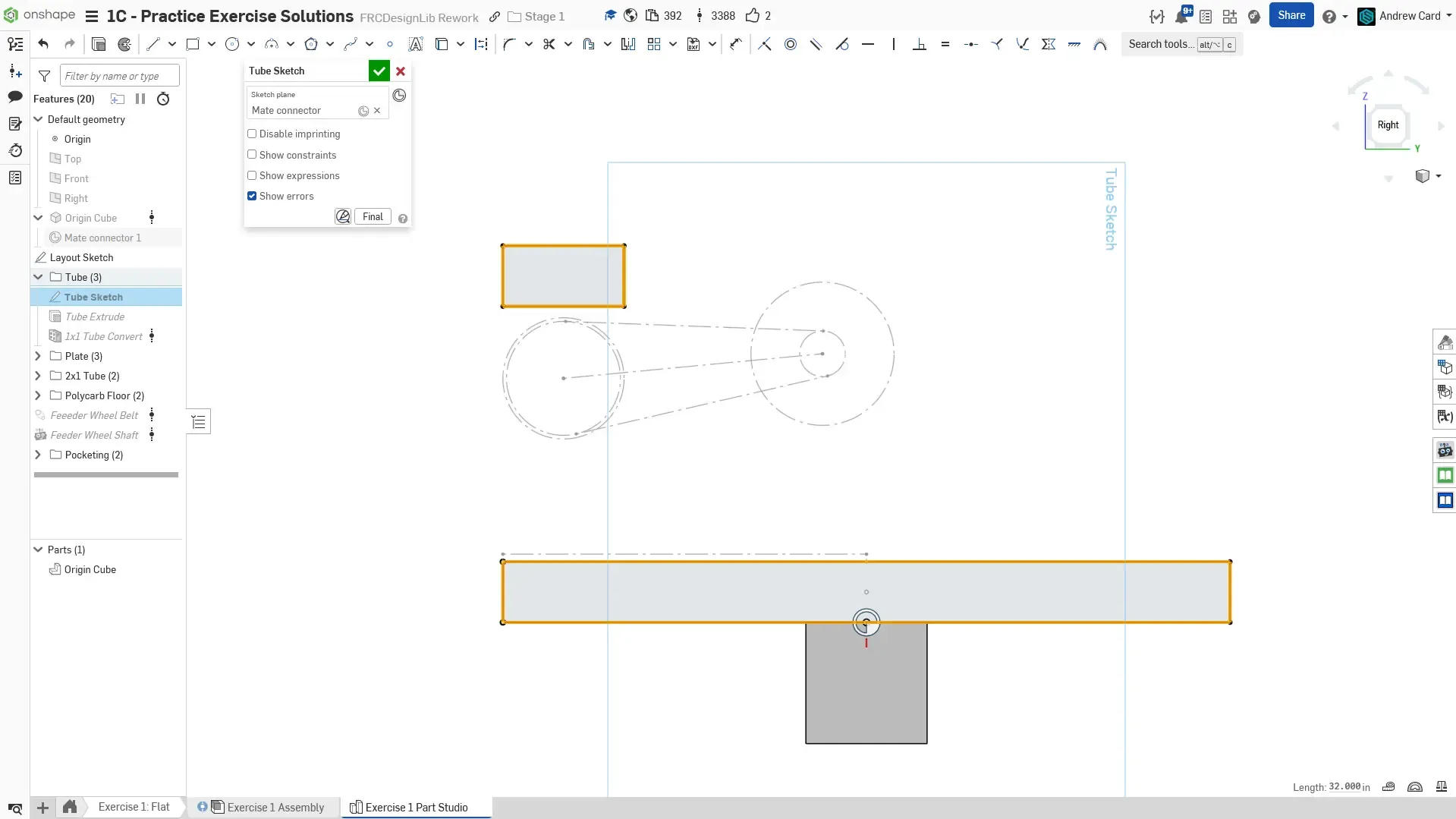

Section titled “Part Studio Instructions”Navigate to the “Exercise #1 Part Studio” tab in your copied document and follow the instructions in the slides to complete the part studio for this exercise.

Assembly Instructions

Section titled “Assembly Instructions”Next, navigate to the “Exercise #1 Assembly” tab in your copied document and follow the instructions in the slides to complete this exercise.

Make sure to have you and/or a more experienced member/mentor of your team review your CAD!

Parametric Modeling

Section titled “Parametric Modeling”Some of the steps we took to complete this exercise could have been simplified. For instance, we didn’t necessarily need to make the shaft properly positioned/aligned in the part studio. We didn’t need to use an “Up to face” extrude for the upper tube.

However, we practice these techniques because, while they may marginally increase modeling time upfront, they can save significant amounts of time when going back and editing. CAD is an iterative process - your models and designs won’t be perfect the first time around, so making your model easier to modify and more robust to changes (e.g., changing the width of this intake) will save you time and effort in the long run. As you use best practices, they’ll become second nature.

Try playing around to get a feel for what things are and aren’t parametric in exercise 1. You can try changing things like the width, length, tube positions, or gear ratio. Which dimensions are easy to change and which are difficult? Which dimension changes cause rebuild or assembly error?